| Sign In | Join Free | My chinaqualitycrafts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinaqualitycrafts.com |

|

Brand Name : HAIJIA

Model Number : HJF240

Certification : ISO CE SGS

Place of Origin : zhejiang,china

MOQ : 1

Price : 23300-27000USD

Payment Terms : L/C, D/A, T/T, Western Union

Supply Ability : 100 set per month

Delivery Time : 20days

Packaging Details : 5.4*1.5*2m

screw diameter : 55mm

screw L/D ratio : 20L/D

shot size(theoretical) : 593cm3

injection weight(PS) : 534g

injection rate : 179g/s

injection pressure : 160.8Mpa

screw speed : 0-180rpm

clamp tonnage : 2400kN

toggle stroke : 490mm

space between tie bars : 530*510mm

ejector stroke : 165mm

ejector tonnage : 70kN

max.pump pressure : 16Mpa

pump motor power : 18.5kW

heater power : 11.65kW

machine weight : 7

oil tank capacity : 340

Style : Horizontal,Vertical

Condition : New

Automatic : Yes,Full automatic

Type : Preform Injection

After-sales service provided : Engineers available to service machinery overseas,Online support,Field installation,Free spare parts,commissioning and training

Warranty : 2 Years

The popular 240 ton medical syringe injection molding machine

HAIJIANG supply all kinds of injection molding machines from 50T to 3000T, including color chips making machine, energy saving injection molding machine, gears making machine, dual clear color injection molding machine, bakelite injection molding machine, PET preform injection molding machine, Fixed pump and varSaving power plastic injection molding machineiable pump injection molding machine, PVC fitting injection molding machine, screw barrel for injection molding machine etc

240T Injection Molding Machine main technical datas as below:

| SPECIFICATION | HJF240 | |||

| Screw Type | A | B | C | |

| Screw Diameter | Mm | 50 | 55 | 60 |

| Screw L/D Ration | L/D | 22.2 | 20 | 18.2 |

| Shot Size(Theoretical) | cm3 | 508 | 593 | 706 |

| Injection Weight(PS) | g | 462 | 534 | 642 |

| Injection Rate | g/s | 148 | 179 | 202 |

| Injection Pressure | MPa | 180 | 160.8 | 128 |

| Screw Speed | rpm | 0~180 | ||

| Clamping Force | KN | 2400 | ||

| Opening stroke | Mm | 490 | ||

| Space Between Tie Bars | mm | 530*510 | ||

| Max.Mold Height | mm | 530 | ||

| Min.Mold Height | mm | 200 | ||

| Ejector Stroke | mm | 165 | ||

| Ejector Tonnage | KN | 70 | ||

| Max.Pump Pressure | MPa | 16 | ||

| Pump Motor Power | KW | 18.5 | ||

| Heater power | KW | 11.65 | ||

| Machine Dimension(L*W*H) | M | 5.4*1.5*2 | ||

| Machine weight | T | 7 | ||

| Oil Tank Capacity | L | 340 | ||

1.Haijiang 240t plastic medical syringe making machine picture display :

2.Key Components on China Ningbo Haijiang Injection Molding Machine

3.The products made by China Ningbo Haijiang Iinjection Molding Machine

4.Auxiliary Equipment for China Ningbo Haijiang Injection Molding Machine

5.Workshop of China Ningbo Haijiang Injection Molding Machine

6.China Ningbo Haijiang attend the China exhibition

7.Quality Control for China Ningbo Haijiang Injection Molding Machine

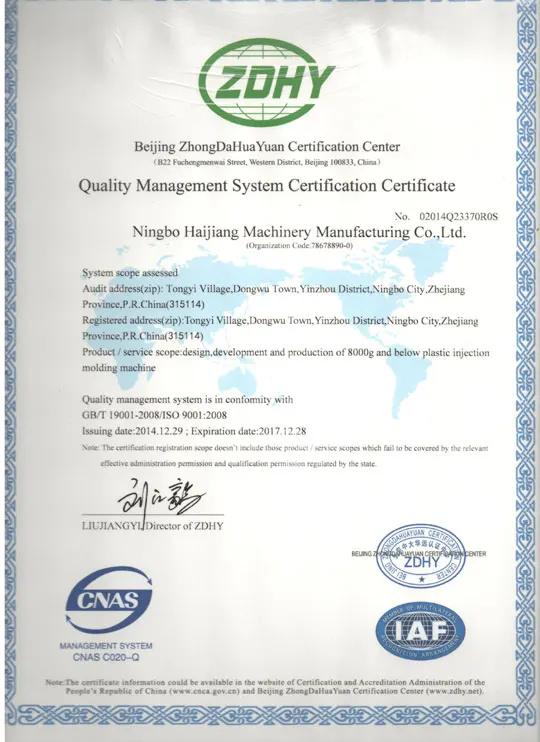

8.CE ,ISO9001-2020 and SGS Certificate for Haijiang Injection Molding Machine

Machine Component:

Controller: Porcheson (Hongkong) Vane Pump: Albert (America)

Directional Valve: Yuken or Northman (Taiwan) Electric Motor: Huanqiu (Dongguan)

Proportional Valve: HNC or Yuken (Taiwan) Encoder: Fort (America)

Solid State Relay: Mager (China) Thermal Overload Relay: Schneider (France)

Five-star hydraulic motor: Dandun (Italy Technology) Lubrication Pump: Omoron (Japan)

Limit Switches: Omoron (Japan) Air Breaker: LG (Korea)

Servo Motor: Yunsheng (China) (For servo motor machine only)

Servo Pump: Sumitomo (Japan) (For servo motor machine only)

Servo Driver: Delta (Taiwan) (For servo motor machine only)

Free spare parts come with injection machine:

Mold clamping and bolts: 8PCS, Nozzles: 2PCS, Toolbox: 1SET, Heating Ring: 2PCS,

Lubrication Oil: 1 Bucket, Limit Switch: 2PCS, Hexagon Wrench: 1SET,

Thermocouple: 2PCS, Seal Ring: 2PCS, Power socket for auxiliary machines: 2PCS,

Wrench: 1PCS, Screwdriver: 2PCS, Vise: 1PCS, Machine shockproof pads: 6PCS

Solve some problems

Q1. What is the warranty for the plastic injection molding machine

A1:Total 18 month,Included machine platen,base,injection unit,clamping unit.

Q2:Can you sending engineer to oversea install machine and trainning customer's workers.

A1: Yes,We will send engineer to customer factory install the machine or trainning customer's workers. in one week,total free.

After one week, 100$ per day

Q3:How Many spare parts you will prepare for customer?

A3: Spare parts included: mould clamp, long and short nozzle,heating band,Wrench,Switch,Thermocouple,Operation manual

Tool box,Lubricate Oil,Sealing,Filter etc.

Q4:Computer sytem,Except English, can you change other language,say: French,Spanish,Arabic,Russian.

A1:Yes,when you place order,please tell us the language which you required. Standard one with English,Japanese,Chinese,Korea.

Q5:Can you change the power source for us? Say:we need 3 Phase 220V 60HZ

A5: When you place order,please write clearly.Then we will change the electric system for you.

Q6:If i Need Green Color machine,can you do it for us?

Q7: Yes,please give us the color sample.So we can do it for you.

Are you interested ?if yes ,you can direct contact with me:

whatsapp : 008615168132230

wechat:15168132230

emial :haijia08@china -haijiang.com

Inquiry now !

|

|

full production line for syringe making machine syringe size from 1ml,2ml,3ml,5ml,10ml,20ml,50ml Images |